Smart Maintenance

Optimising Maintenance

Smart Maintenance in respect of track maintenance covers elements as maintaining rail or track alignments, vegetation control, objects control, smart track data management and smart track.

In addition terms as SmartTamp and InnoTamp are used frequently. In the end, all this terminology could be part of a good BIM.

Spocior, in cooperation with Fugro RailData and Network Rail (UK), developed the concept of Smart Maintenance.

Spocior commissioned by Fugro RailData and in cooperation with Network Rail (UK) has expanded the concept of Smart Maintenance for track. This project, called InnoTamp, was financed by Innovate UK, commissioned by Department for Transport.

This project covers a with range of aspects. It starts with highly accurate survey of the rail corridor. Not only the track position in XYZ coordinates with geodetically precision but also all track safety parameters as formulated in EN 848 standard such as track gauge, twist, D1, D2 and D3 wave length defects. Also in the same survey all objects (platforms, signal posts, tunnels, adjacent track, etc) including the wires and masts of the overhead line construction are recorded.

This (BIM) data-set creates the opportunity to identify those track segments in need of maintenance. Using the same data-set, an optimal track alignment is generated for these track segments, followed by an automated generated list of horizontal and vertical track movements in order to achieve the optimised alignment by tamping. Next, this generated rail movement list is uploaded directly into the alignment computer of the track maintenance machine, a so-called tamper.

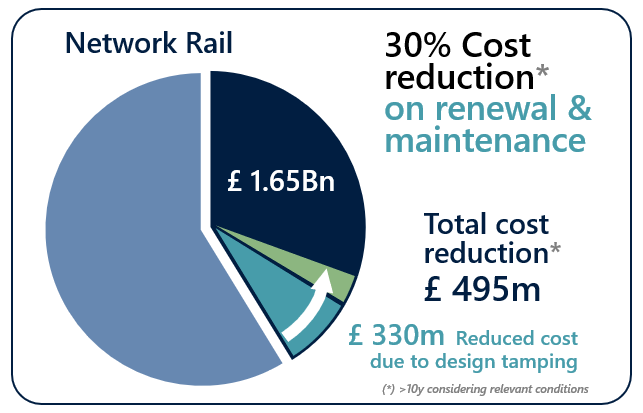

Because the geospatial position of all objects in relation to the track position are known, an automated process checks whether the sufficient space between the objects and trains remains after the tamping has taken place. This InnoTamp project was able to underpin significant savings in track maintenance.